Highly pigmented waterborne pore filler for engineered wood products

Acts as a base and mid coat on wood and engineered wood products in indoor areas, for example MDF boards.

| COLOUR CODE | CAN SIZE LITRE | ARTICLE NUMBER | |

|---|---|---|---|

| 2.50 | 11102030 | |

| 11102032 |

NUMBER OF COATS

One coat is sufficient; a top coat is absolutely essential.

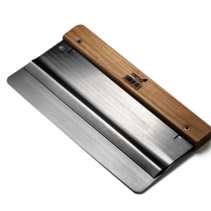

TOOLS

Finished surface in 1 day, 1 coat (top coat required)

- First coat: Flow cup spray gun: nozzle: 2.0-2.5mm, vaporiser air pressure: 1.6-2.2 bar; Airless: nozzle: 0.23-0.28 mm, material pressure: 80-120 bar; Airmix: nozzle: 0.23-0.28 mm, material pressure: 80-100 bar, vaporiser air pressure: 1.2-1.8 bar. Application amount depends on engineered wood product and surface quality, among other things, approx. 200-300 ml/m².

- Drying time: under normal climatic conditions, 20-23 °C/50-65 % rel. humidity, dust-dry: approx. 2-3 hours; recoatable approx. 4-5 hours. Forced drying (~50 °C circulating air), dust-dry: approx. 10-15 minutes; recoatable approx. 45-60 minutes.

- Sand the dry coating, grit P240-360, and remove any sanding dust.

- Repeat Steps 1-3 if necessary, for example on highly absorbent substrates such as milled areas or edges of MDF boards.

- As a high-quality top coat, an opaque Osmo Spray-Wax is recommended.

HOW MUCH COATING DO I NEED?

With our finish calculator, the right amount of coating necessary for your project can be calculated quickly and easily.

Please follow our advice in the product information sheets for the correct application.